SLM

Laser sintering

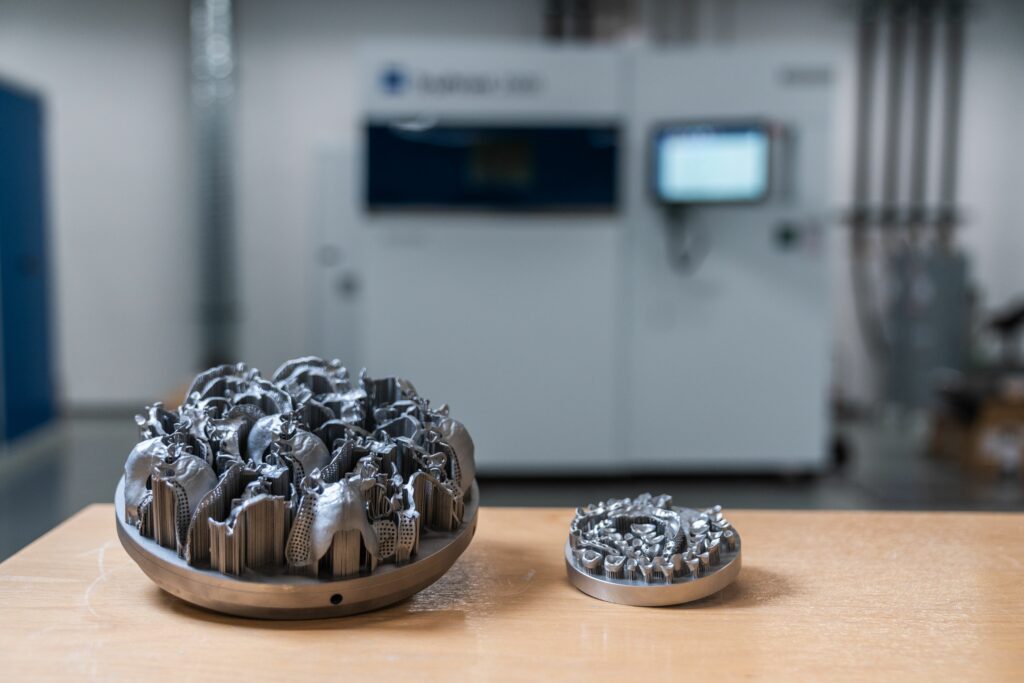

In addition to milling of conventional materials, our production CAD/CAM centre also offers the so-called selective laser burnishing (SLM) method.

This works by melting the metal powder layer by layer into the desired shapes using a laser beam. Thanks to this extremely advanced production technology, maximum precision and homogeneous structure are thus achieved, while at the same time low costs are also achieved, which are reflected in an attractive price.

Tip: We are currently preparing the possibility to produce bridges or bars fixed by implants where fitting is after-milled then.

Additive laser melting technique

This manufacturing technique has been used primarily for CoCr or titanium crowns and bridges in the dental industry for quite some time. Since milling such products is not economically very profitable, laser sintering is a way to produce them quickly and cost-effectively.

Thanks to selective laser melting, very complex and accurate shapes can be produced.

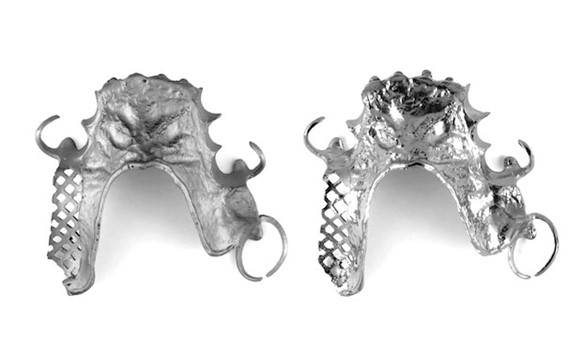

3D printing of RPD

Save your time and hands with us.

Removable partial dentures made of CoCr or titanium are time consuming for the technician and unproductive as a process. CAD/CAM technology eliminates model blocking, duplication, casting, sanding, polishing, etc.

Send us the .STL files of RPD design or just a scan or plaster model and let us make a design to you.

i

- Send STL data or scans via the customer portal or use our order form

- If your .STL data are received by 3:00 pm, we will ship the finished RPD in 76 hours.

- If you ask for a RPD design, you should count with maximum of 5 business days since order placed to delivery.

- The complete CoCr RPD costs 99.99 EUR without polishing.

- If you ask also to be polished, you will pay 109.99 EUR. The RPD design will cost you an extra 20 EUR/pc.